This page has moved to http://www.grecobrothers.com/displacement-dryers.html |

SPOT-FREE

Displacement Drying Systems

Stainless Steel Construction

150% Freeboard

Drop-Seal cover

Continuous Filtration

Sub-zero Freeboard Chiller

Sweep frequency ultrasonics

Automated Shutdown Cycle

Greco Brothers Spot-Free Displacement Drying Systems are the state of the art in part drying technology. By displacing the water from the part rather than evaporating it, these systems are capable of producing spot-free parts which are thoroughly dry and free of water stains, mineral salts and other residual soils.

How

Displacement Drying Works

How

Displacement Drying Works

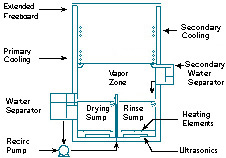

The Greco Brothers displacement drying system is fully integrated; consisting of a drying sump, a rinse sump, primary and secondary water separators, primary and secondary cooling systems, and a filtered recirculation system.

Fast, spot-free drying can be accomplished because of the relatively high specific gravity of the drying fluids and their drying agent, which encourages rapid displacement of water from part surfaces.

Operating Procedure

The wet parts are immersed in the drying chamber. As the water is displaced, it rises to the surface. The water is then skimmed over a weir, into a water separator and to drain. Next the parts are removed from the drying sump and placed in the rinse sump to remove any drying agent residue. After immersion rinsing, the parts are given a final vapor rinse and are removed ­ dry and stain-free.

Why a Greco Brothers Drying System?

Greco Brothers has been a leading

manufacturer of cleaning and drying equipment for fifty years.

Our Displacement Drying Systems are designed to maximize drying

effectiveness, operating efficiency, and dependability while meeting

the needs of your specific drying application.We combine high

turnover rates, continuous filtration, liquid agitation and ultrasonic

cavitation in a design that ensures the most effective drying

system available-and one that requires a minimum of floor space.

All models are designed with special features that drastically

reduce vapor emissions. In addition to the primary and secondary

refrigerated cooling systems, we provide a shut-down cycle which

operates after the dryer's work is done. While in shut-down mode,

the refrigerant in the primary cooling system is diverted to special

cooling coils in the boil and rinse compartments.  This system quickly cools

the liquid,

while the secondary refrigeration system continues to condense

any residual vapors. As final insurance against downtime losses,

all Greco Brothers Displacement Drying systems come with our patented

Drop-Seal Cover which rolls into position and seals the vapors

in the machine. Best of all, with Greco Brothers equipment you

get the quality workmanship that our customers have come to expect

from us over the last fifty years. The entire body of our dryers,

along with all components and framework are constructed exclusively

from heli-arc welded stainless steel-ensuring long equipment life

and satisfied customers.

This system quickly cools

the liquid,

while the secondary refrigeration system continues to condense

any residual vapors. As final insurance against downtime losses,

all Greco Brothers Displacement Drying systems come with our patented

Drop-Seal Cover which rolls into position and seals the vapors

in the machine. Best of all, with Greco Brothers equipment you

get the quality workmanship that our customers have come to expect

from us over the last fifty years. The entire body of our dryers,

along with all components and framework are constructed exclusively

from heli-arc welded stainless steel-ensuring long equipment life

and satisfied customers.

For more information, call Greco Brothers. We will be pleased to help you choose the high-performance drying system that best meets your requirements.

Applications

Nearly any water-wet part can be dried using a Greco Brothers Spot-Free Displacement Dryer. Complex part configuration and stringent tolerances for surface contamination are no longer a drying problem. These systems are designed to meet the drying requirements of critical electromechanical assemblies, optical elements and lenses, computer components, medical devices, aerospace components, and nearly any water-wet part. And best of all, Greco Brothers displacement parts dryers utilize fluids which are non-toxic, and non ozone-depleting.

|

|

|

|

![[Logo]](logogbonwhite.gif)